Background

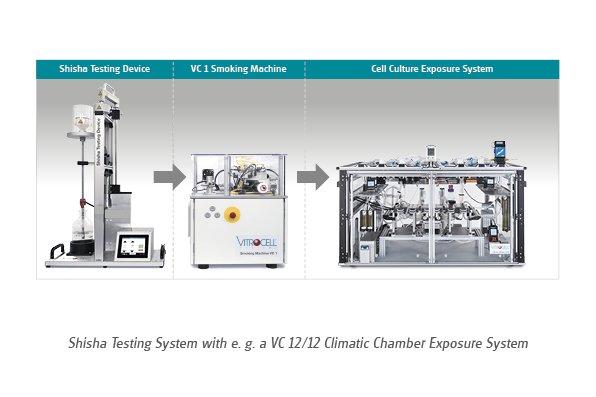

Emissions of water pipe tobacco can now be tested by in vitro exposure in a reliable and user-friendly setup. The novel Shisha Testing Device can be combined with any VITROCELL® Exposure System. The same setup can also be expanded for chemical analysis of Shisha emissions.

Solution

The Shisha Testing System consists of the following components:

1. Shisha Testing Device

2. VC 1 Smoking Machine

3. Cell Culture Exposure System

1. Shisha Testing Device

The device follows the specifications of ISO 22486. The system can be operated with charcoal or via electrical heating. The water pipe tobacco holder is made of ceramics and holds approx. 25 ml of tobacco.

The electrical heating is precision-controlled in the range of 280 ± 10 ºC. Alternatively a charcoal operation is possible.

The Shisha testing device comes with a set of useful tools for user-friendly operation.

2. VC 1 Smoking Machine

All parameters for smoking such as puff volume, frequency, puff duration and puff profiles are set according to ISO 22486 in the controls of the manual smoking machine VC 1. This device is specifically designed to fulfill the requirements of in vitro experiments and analytical testing.

The machine is also suitable for conventional and electronic cigarettes. For this purpose it can be equipped with different cylinder sizes (200, 300 and 600 ml) without compromising the accuracy of the puff profile. The conversion procedure to the higher/smaller cylinder size is possible within less than 10 minutes.

This makes the investment very versatile as testing of all combustion cigarettes, cigars, ENDS (Electronic Nicotine Delivery Systems) as well as HTP’s (Heated Tobacco Products) is possible with only one machine.

3. Cell Culture Exposure System for the Air/Liquid Interface

In response to the scientific need to expose in physiologically relevant conditions, VITROCELL® Exposure devices have been specifically designed to enable direct exposure of mammalian cells or tissue at the Air / Liquid Interface.

Here the cell cultures are not covered with media as opposed to submerged conditions – which cause an undesired interaction of the formerly airborne substances with the culture media.

Cell systems cultivated on membrane inserts are exposed at the Air/Liquid Interface (ALI) so that the test substances are received directly. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

The VITROCELL® product range covers a wide range of solutions for exposure from 6 to 56 cell culture inserts in different dilution steps.

Key Features:

– Puff duration: 2.6 s ± 0.1 s

– Puff volume: 530 ml ± 10 ml

– Puff frequency: 20 s ± 0.5 s

– Square puff profile

– Electrical heating: 280 °C ± 10 °C

– Versatile Smoking Machine

– User-friendly temperature control unit

– Suitable for chemical and biological testing

Images

Photo 1: Shisha Testing System with e. g. a VC 12/12 Climatic Chamber Exposure System

Photo 2: Shisha Testing Device

Photo 3: Integrated electrical heating device

Photo 4: Heating via charcoal

Photo 5: Controller for heating with touchscreen display

Photo 6: Tools for user-friendly operation

Photo 7: VC 1 Smoking Machine

Photo 8: VC 1 can be equipped with different cylinder sizes (200, 300 and 600 ml)

Graph 1: Air / Liquid Cultivation and Exposure in Exposure Module

Graph 2: Direct Exposure Technology at Air/Liquid Interface

Advanced in vitro exposure systems

VITROCELL Systems GmbH

Fabrik Sonntag 3

79183 Waldkirch

Telefon: +49 (7681) 4977950

http://www.vitrocell.com

Managing Director

Telefon: +49 (7681) 4977950

Fax: +49 (7681) 4354

E-Mail: info@vitrocell.com

![]()